Thesis

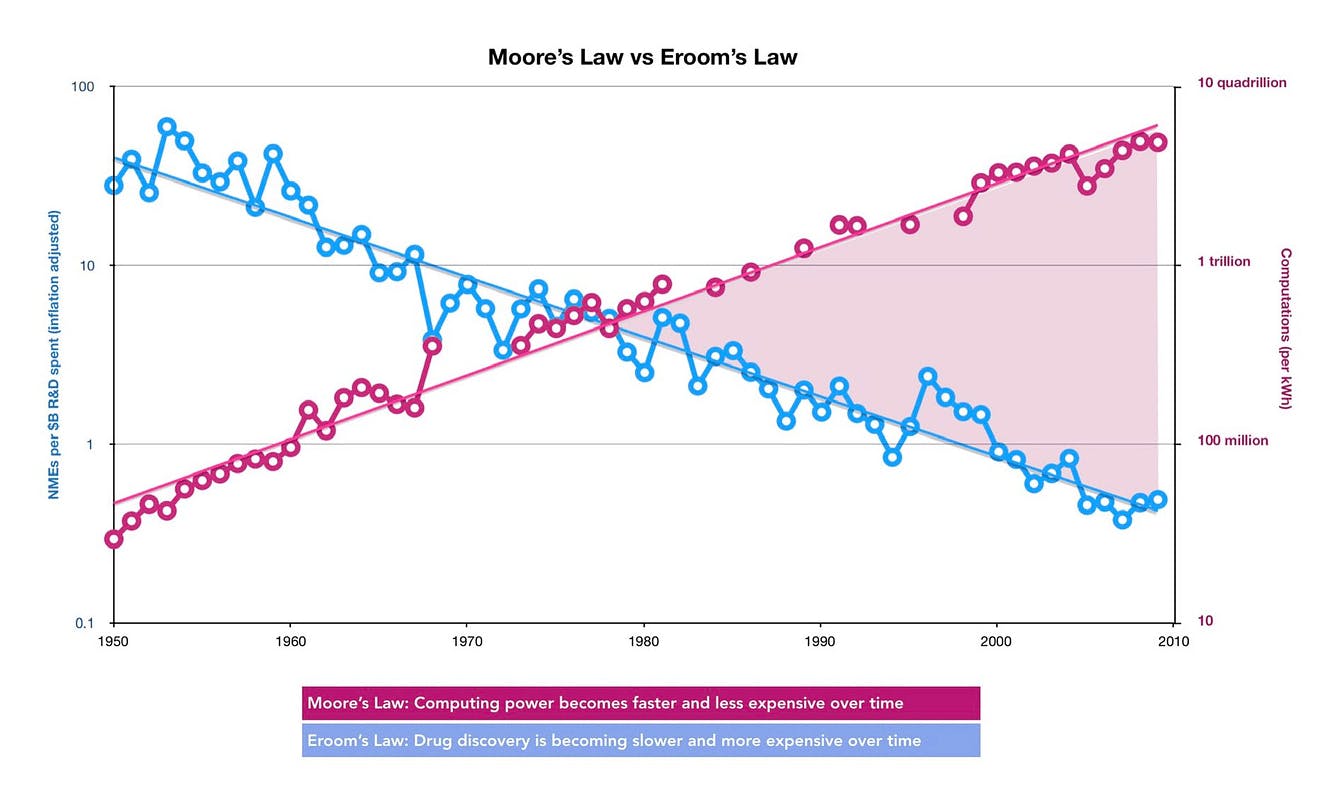

The semiconductor industry has rapidly advanced in lockstep with Moore's Law since the 1970s, which predicted the doubling of chip performance every two years. Meanwhile, the biopharmaceutical industry contends with the opposite phenomenon known as Eroom's Law. Drug development costs for a single successful drug have soared from $225 million in 1979 (adjusted for inflation) to $2.5 billion in 2023, signaling a critical decline in pharmaceutical innovation efficiency. This stagnation in biomedical productivity has driven the search for breakthrough approaches that could reverse this trend, primarily by finding solutions to improve molecular synthesis quality or reduce production costs for pharmaceutical ingredients.

Source: Unlearn.ai

One such solution is in-space manufacturing of pharmaceuticals, as the unique microgravity condition of outer space enables novel synthesis methods to produce pharmaceutical ingredients otherwise extremely difficult to generate under Earth’s gravity. While in-space manufacturing has historically been limited to research experiments on the International Space Station (ISS), the rapid reduction in launch costs because of SpaceX has created economic incentives for commercial microgravity manufacturing at scale.

Varda Space Industries provides a full-stack service for in-space pharmaceutical manufacturing through its Winnebago Series (W-Series) capsules. These autonomous capsules combine manufacturing and re-entry capabilities, eliminating dependency on the ISS while facilitating the development and return of space-processed pharmaceuticals. Beyond pharmaceutical clients, Varda's re-entry system doubles as a hypersonic testing platform for the military.

Founding Story

Source: CNBC

Varda Space Industries was founded in late 2020 by Will Bruey (CEO), Delian Asparouhov (Chairman and President), and Daniel Marshall (former Chief Scientist).

The original concept behind Varda was devised by Asparouhov, who was fascinated with space in his high school years and interned at NASA JPL as a high schooler. He then studied computer science at MIT and later interned at Square in 2012, which inspired Asparouhov to start his own company. He applied for and won the Thiel Fellowship, which led him to drop out and work on Nightingale, a healthcare startup. Despite receiving an initial $600K investment from Y Combinator’s 2014 Summer batch, the company flatlined at $15K MRR and could not raise a Series A, prompting Asparouhov to quit.

Although Asparouhov wanted to launch another startup immediately afterward, he was persuaded to join Khosla Ventures as the Chief of Staff to Keith Rabois and eventually promoted to Principal in August 2018. One of his first investments at Khosla was in Akash Systems. Collaborating with its founders helped Asparouhov realize that the timeframes and costs associated with working in space could be significantly reduced due to SpaceX’s impact on space launch economics. When Keith Rabois left Khosla for Founders Fund, Asparouhov followed and became a Partner at Founders Fund in March 2019. By 2020, Asparouhov was inspired by Rabois to begin another startup and came up with the following thesis: an in-space manufacturing startup that could operate independently of the ISS. Varda was incubated and created at Founders Fund.

Asparouhov recognized that the primary engineering challenge for Varda's success was safely bringing manufactured materials back to Earth through low-cost re-entry vehicles. Through his close friend at MIT, who had become a senior executive at SpaceX, he connected with Bruey and began recruiting him as a co-founder.

Bruey graduated from Cornell in 2012, where he spent several years working on satellite systems at Cornell’s Space Systems Design Studio before working at SpaceX for over five years. There, he was the lead hardware engineer on the Falcon rocket and Dragon capsule, one of two successful re-entry vehicles designed by private companies. Bruey also flew nine missions to the ISS as a mission control spacecraft operator, making him experienced in both the design and operation of re-entry spacecraft. After his five-year stint at SpaceX, Bruey also worked as the Director of Global Equities Technology at the Bank of America to gain experience in finance before being recruited by Asparouhov to co-found Varda.

In November 2020, Asparouhov and Bruey incorporated Varda, naming it after the Queen of Valar from Lord of the Rings, who created the stars out of morning dew. Less than a month later, they raised a $9 million seed round co-led by Founders Fund and Lux Capital, then a $42 million Series A just seven months later.

Varda has since expanded its leadership team. In 2023, Nicholas Cialdella advanced from Head of Vehicles to Chief Technology Officer (CTO), bringing eight years of SpaceX avionics and systems integration experience. Adrian Rodocea transitioned from Head of Product to Chief Scientist in 2022, replacing Marshall after he left the firm. Richard Wissemann joined as Director of Avionics in 2021, contributing hardware engineering expertise from Apple, Blue Origin, and SpaceX.

Product

Varda's factory satellites consist of a three-piece vehicle: a satellite bus, a manufacturing module, and a heat shield-protected re-entry capsule. While Varda designs and manufactures the manufacturing module and re-entry capsule internally, the company partners with SpaceX to use its Falcon 9 rockets for launch capabilities and with Rocket Lab to use its Photon spacecraft for orbital operations, including spacecraft propulsion, avionics, and communication. To return the capsule to Earth, the Photon spacecraft will slow down to de-orbit and separate from Varda’s capsule. Photon will burn up during re-entry, while the capsule will descend at hypersonic speeds, experiencing up to 12g of deceleration — high enough to kill a human within seconds. The capsule uses an ablative heat shield (made of C-PICA) that can withstand over 1K°C temperatures during the re-entry phase, keeping internal temperatures low enough to ensure that pharmaceutical samples aren’t compromised.